Full range of metal processing

From cutting, through welding and bending, to finishing

Welding TIG MAG MIG

We weld carbon steel, stainless steel, and aluminum. Our welders hold up-to-date certifications and undergo regular training. We ensure weld quality and dimensional accuracy – even with complex structures that must assemble without issues after welding.

CNC Machining

Turning and milling with tolerance down to 0.05 mm. We work in Fusion 360 (CAD/CAM), so from drawing to finished part, everything is done under one roof. We machine steel, aluminum, and engineering plastics (polyacetal).

Cutting

Band saw for profiles and bars, plasma cutter for sheet metal up to 20 mm thick. We prepare material for further processing or deliver finished components according to documentation.

Bending

CNC press brake (80 tons, up to 3 m length), tube bender (up to Ø33 mm), 100-ton hydraulic press for stamping and forming. We bend sheets, profiles, and tubes – from single pieces to short runs.

Finishing

We coordinate the entire process with trusted partners – you receive a finished product without searching for additional contractors.

Aluminum anodizing

We coordinate anodizing with trusted partners. We deliver finished aluminum components – colored or natural. You don’t search for subcontractors.

Powder coating

We organize powder coating for steel and aluminum. You receive a finished component in your chosen color, protected and ready for assembly.

Galvanizing

Hot-dip or electroplating – we select the method based on application and customer requirements. We send to the galvanizing plant, collect, and deliver the finished product to you.

How we work

Short runs require flexibility, not rigid procedures. We talk, clarify details, verify documentation, and only then provide a quote. If something is missing from the drawings, we’ll ask or complete it ourselves. We want the product to come out right the first time.

01

Inquiry

You send documentation

02

Verification

We check feasibility

03

Quote

We set the price and timeline

04

Production

We execute the order

05

Delivery

We ship the finished product

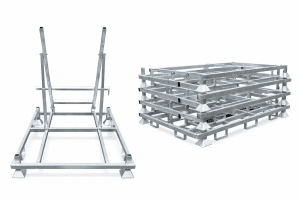

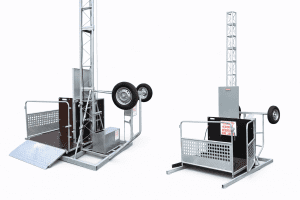

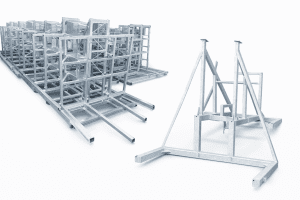

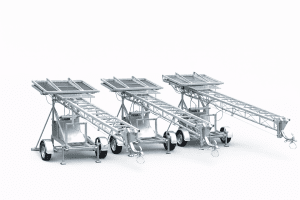

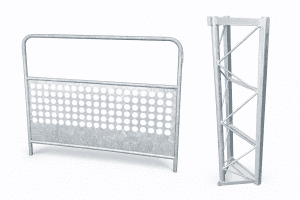

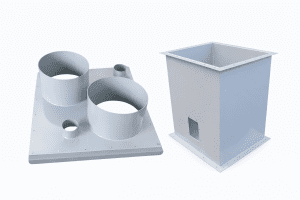

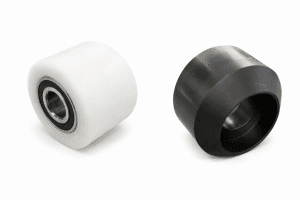

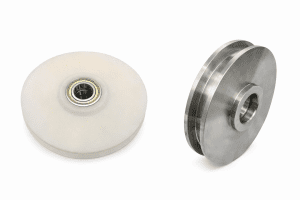

Selected projects

Machine frames, rope sheaves, steel pallets, lift and construction crane components – from a single detail to a complete subassembly that the customer installs on-site.

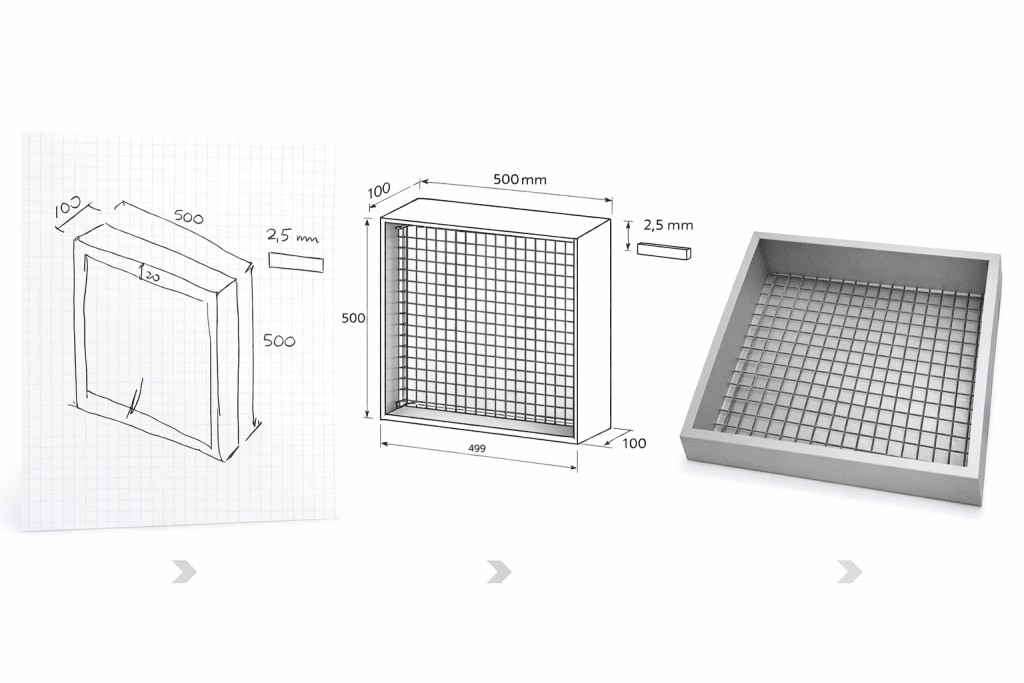

Have an idea? We'll help you make it happen

Technical support

You don’t need finished documentation or even a sketch. Just tell us what you want to achieve — together we’ll sketch it out, prepare the documentation, and bring it to a finished product.

- A verbal description, sketch, or photo is enough to start

- Together we'll refine dimensions, materials, and finishing

- We create complete manufacturing documentation in CAD

- We advise how to optimize the design

- We handle production and deliver the finished component

We verify feasibility, advise on optimizing the design and finishing. We create appropriate manufacturing documentation in CAD.

Machinery

A compact machine park allows us to handle the entire process — from cutting, through bending and welding, to machining. We don’t have production lines for thousands of pieces, but we have everything needed for short runs with precision.

| Machine | Parameters |

|---|---|

| CNC press brake | 80 tons, 3 m |

| Hydraulic press | 100 tons |

| Tube bender | Up to Ø33 mm |

| CNC lathe | |

| CNC milling machine | |

| Band saw | |

| Plasma cutter | Up to 20 mm |

| Forklift | 2.5 tons |

Let's talk

Have a project or concept?

Send an inquiry, attach documentation, we’ll respond quickly.

or call